Testing Services.

We provide a wide range of testing services for aerospace and industrial applications in our facilities in Switzerland, Sweden, Germany, Austria, Finland and the US.

Over four decades of experience in testing services.

Beyond Gravity has been involved in space missions since the first space missions in the early 1970s. For us, reliability, meticulous planning and, not least, rigorous testing are important and vital parts in the development of components, electronics and structures for use in space. With our long-standing experience and extensive knowledge we are able to test a wide range of materials and products in our test facilities in Switzerland, Sweden, Germany, Austria, Finland and the US. The testing for qualification and testing of flight hardware and industrial products is one of our core competences. This includes destructive as well as non-destructive testing.

Mechanical and Structural Testing

Beyond Gravity has a long-standing history in the management and execution of mechanical and structural testing. The extensive experience and expertise gained over many years of testing internal projects, combined with the specialized testing equipment developed during this time, ensures that a reliable partner is also available to external customers for all testing services

Static Load Testing

Several test rigs of different sizes are available for large-scale structural testing under static loading. The 10-meter static load test rig is the largest test rig in Europe. The flexible design of the static load test rig allows us to apply high loads in all directions simultaneously. Large structures can be measured with photogrammetry and tracked in their movement.

Separation Test

A comprehensive separation test, including a pyrotechnic separation test, can be performed to measure and analyze the shocks that affect the spacecraft as it separates from the final stage of the rocket. Laser trackers, strain gages, accelerometers, thermocouples, high-speed cameras, and state-of-the-art tracking software are used to measure, detect, and document these tests.

Modal Survey – Structural Dynamic Characterization of Components

In our structural test center, the structural dynamic characterization of components can be determined through experimental modal measurement tests. Modal tests provide the opportunity to simulate and understand the dynamic behavior of structures and to determine the cause of noise and vibration phenomena.

Materials Testing and Non-Destructive Testing (NDT)

The Beyond Gravity Materials Test Lab is certified for non-destructive inspection (NDI) of composite structures and equipped to measure physical properties of materials. X-ray analysis, microscopy, friction, and dye penetrant testing are also part of the expertise that our specialists can offer as a service to external customers and for our own projects.

Hardness Test – Determination of material properties

Equipped with multi-purpose and micro hardness measuring instruments from Leica and Gnehm, the materials testing laboratory can determine the Vickers, Brinell and Rockwell hardness of materials.

With our portable testing equipment, it is also possible to perform on-site measurements to determine hardness.

- Vickers hardness

- Brinell hardness

- Rockwell hardness

- Shore hardness

- Leeb hardness

- Hardness gradient in materials

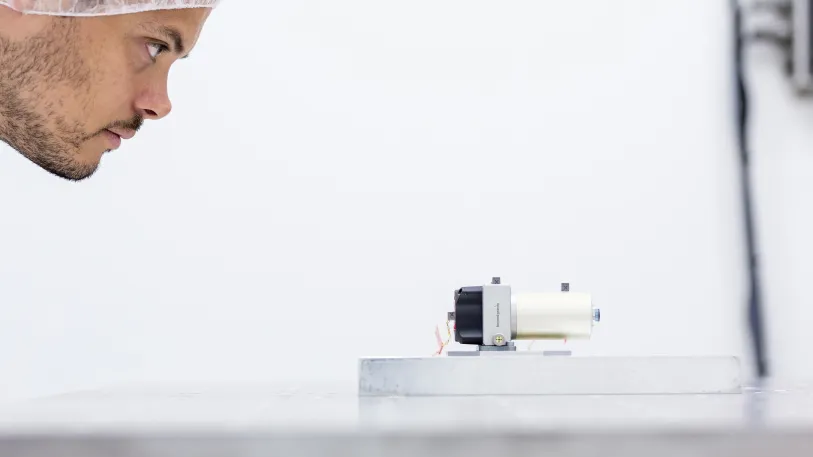

X-Ray Fluorescence (XRF Testing)

With our XRF analyzers from Fisherscope and Delta X, the alloy composition of a sample can be determined in seconds. XRF analysis allows for verification and identification of metals in a non-destructive manner. This instrument uses X-rays and measures the fluorescent X-rays specific to each element. Almost all metals and other trace elements can be detected. Beyond Gravity offers XRF testing in our facilities or on-site.

- Determination of alloy composition

- Detection of trace elements

Optical Microscopy and Scanning Electron Microscopy (SEM) Inspections

Light microscopes, stereoscopes, and scanning electron microscopes are available to examine microsections, as well as other specimens in greater detail, offering 2 nm resolution and magnification up to 2.4 million times. Grain structures of etched metal surfaces can be visualized with polarized light, for which a range of polarizing filters is available.

Microscopy is also used for many other purposes, such as determining fibers, volume content, microstructures, pore content, coating thickness, and detecting non-metallic inclusions in stainless steels.

- Microstructure

- Texture gradient

- Fiber volume content

- Porosity content

- Thickness of coating

Electrical Conductivity Test (SIGMATEST)

The Materials Testing Laboratory offers electrical conductivity testing to determine the film thickness of organic coatings on non-ferromagnetic substrates. A portable tester, Olympus NORTEC 600, uses the eddy current method. The method is mainly used to determine the thickness of “Ematal” coatings, a mineral-based coating used to protect metals in harsh environments.

- Thickness of the coating

- Mostly used for “Ematal” coatings

With the Olympus NORTEC 600 instrument it is also possible to determine the specific electrical conductivity of non-ferromagnetic electrical conductors. In combination with hardness measurements or XRF tests, it is thus possible to determine not only the alloy composition of a sample, but also its condition.

- Conductivity measurement

- Determination of the heat treatment conditions of aluminum

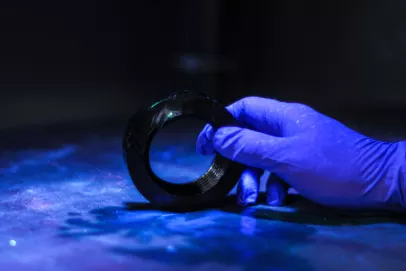

Dye Penetration Inspection (DPI)

Liquid penetrant inspection (LPI) or penetrant testing (PT) is one of the most commonly used non-destructive testing (NDT) methods. This NDT procedure is a cost-effective method for locating surface cracks or other surface interruptions. The dye penetrant testing facility in Zurich is part of the Beyond Gravity Materials Testing Lab. Small batches or one-off products can be flexibly and quickly assessed in our stationary facility by our EN 4179 / NAS 410 certified experts.

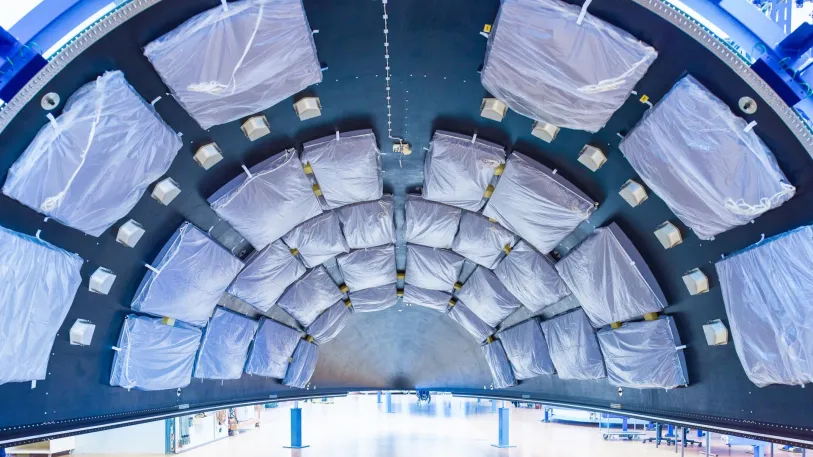

Ultrasound Testing

Acoustic emission and ultrasonic testing are two non-destructive testing (NDT) methods that can help detect and evaluate defects, cracks, corrosion and other flaws in mechanical components and structures. Ultrasound testing provides an ideal platform for non-destructive inspection (NDI) of materials and structural health monitoring (SHM).

For composites, it is critical that CFRP panels are free of delamination. For this reason, we invest considerable effort in non-destructive testing (NDT) using ultrasonic testing and acoustic emission testing. In acoustic emission testing (AET), the interference pattern of reflected sound waves provides information about the composite properties of laminates and sandwich structures. Ultrasonic testing (UT) uses high-frequency sound waves to examine the internal structure of a material or structure. The portable devices offer a high degree of flexibility and can be used for both large and small structures.

Tensile Testing

Our tensile testing machines can provide results for tensile, compression, bending and shear force tests. Zwick, Shimadzu, and Instron tensile testing machines are most commonly used for tension and compression tests. Strain gauges and displacement transducers provide a tool for very accurate determination of displacements. Forces up to 250 kN can be applied.

Heat chambers attached to the tensile testing machines allow testing between -160°C and 350°C. Specialized equipment also allows for evaluation of bending and shear properties.

Bolt Testing

Our bolt testers can be used to test and evaluate thread torque, bolt head torque and bolt tension. With our wide range of standard or custom adapters, we can create truly representative conditions for the bolted joint, right down to the correct surface finish.

Friction Testing

Our friction test rig allows us to determine the resulting friction and wear when combining different surface treatments. Our test rig consists of a rigid frame with two hydraulic cylinders and load cells, one each for the force to provide normal pressure and the force to push the test sample. The coefficient of friction is calculated from the measured values of the two pressure forces.

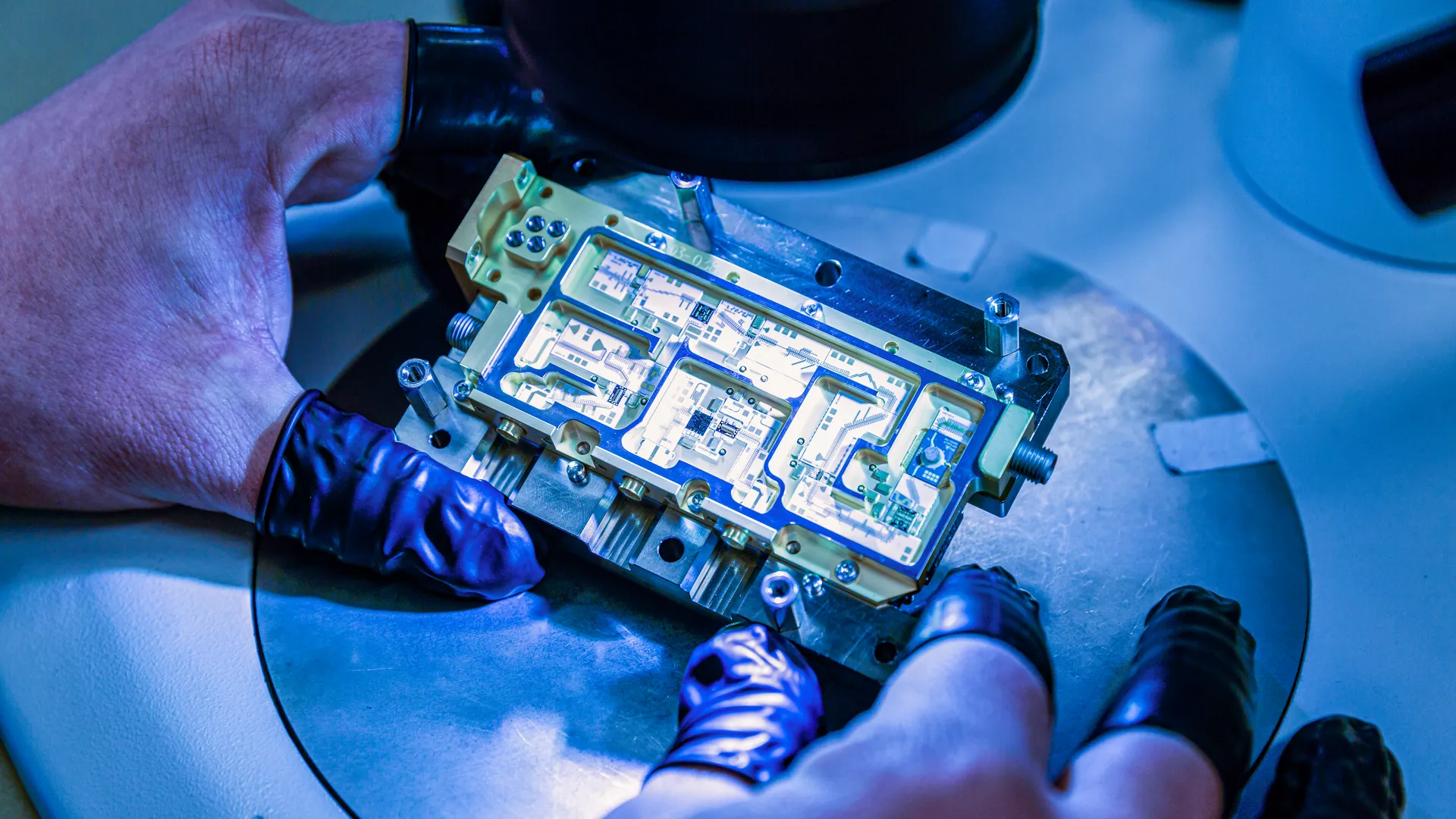

Electronic Components

Beyond Gravity Test Center has the equipment and technical expertise when it comes to testing electrical components and circuit boards. We are able to evaluate the performance, function and quality of both surface mount and hole mount components. We can determine and evaluate the bonding characteristics of solder joints and use X-ray equipment to examine the properties of multilayer printed circuit boards (PCB) and the interiors of most types of passive or active electrical components, as well as smaller structures.

Environmental Testing

The Beyond Gravity Test Centers excel in conducting mechanical and climatic environmental testing. Our expertise extends beyond the execution of development and qualification tests to include comprehensive consulting, organization, coordination, and management of test programs within both internal and external facilities for our customers. Elevate your testing possibilities with Beyond Gravity's holistic environmental simulation solutions.

Vibration and Shock Testing

Experience precision and innovation at Beyond Gravity's Environmental Simulation Test Centers. Equipped with a wide range of electro-dynamic shakers, our facilities ensure precise testing of articles in various sizes and weights across both horizontal and vertical axes. The majority of our vibration test equipment is situated in clean room environments.

Discover the power of the Unholtz-Dickie T4000, Switzerland's largest shaker, boasting 178 kN vibration and 534 kN shock force. With a pneumatic auto-centering system, it is capable of testing loads up to 1800 kg in the vertical axis and even more in the horizontal axis. Additionally, one of our temperature chambers is equipped for vibration tests under unique temperature conditions (-60 to +100 °C) using the LDS V850 shaker.

Shock Testing

Explore the possibilities with our MTS Shock machine for precise and high-intensity testing. Unlike traditional shakers, our MTS Shock machine allows for half-sine shock tests under more extreme conditions. Experience testing loads of up to 150 kg both horizontally and vertically, achieving accelerations of up to 2,000 g with pulse durations ranging from 50 to 0.25 ms. Our equipment accommodates diverse testing needs, providing a maximum table size of 69 × 65 cm.

Pyroshock Testing

Elevate your testing standards with precision and expertise. Choose Beyond Gravity Environmental Test Centers for Pyroshock testing that goes beyond expectations. Pyroshock, the dynamic response of a structure to high-frequency, high-amplitude mechanical excitation, is our specialty. Our facilities are designed to handle frequencies over 10 kHz and accelerations exceeding 10,000 g for comprehensive testing.

Centrifuge Testing

Explore high-precision testing at our Swiss Environmental Simulation Test Center. Our large-scale centrifuge accommodates specimens up to 30 kg (50 × 50 × 50 cm) with remarkable g-forces. Achieving rotational speeds up to 215 rpm, we deliver accelerations up to 80 g. Elevate your testing standards with us.

Climatic Testing

Explore advanced environmental simulation at Beyond Gravity test centers. Our facilities feature a range of climatic test chambers, temperature chambers, thermal shock chambers, and altitude chambers. We offer precise control over humidity (10% RH to 98% RH) and temperatures ranging from -75 °C to +300 °C.

Our largest climatic chamber provides a spacious inner area measuring 2,000 x 2,000 x 1,350 mm. Additionally, one of our temperature chambers is equipped for vibration tests under unique temperature conditions (-60 to +100 °C) using the LDS V850 shaker.

Experience the capability of our temperature shock chambers, generating thermal shocks from -190 °C to +200 °C. With our altitude chamber, we can simulate altitudes up to 30,000 meters (down to 4 mbar).

Drop Test

Discover our comprehensive environmental testing capabilities, including precise drop tests designed to simulate common handling errors during cargo loading and unloading processes. Our advanced facilities employ an overhead crane, enabling drop tests with large samples at heights up to 3 meters.

Experience versatility in drop testing surfaces, including concrete, sand, gravel, and wood. Prioritizing safety, our drop tests are remotely controlled, ensuring a secure testing environment.

Thermal Vacuum Testing

Explore vital space equipment testing at our Environmental Simulation Test Centers, featuring state-of-the-art thermal vacuum chambers. These tests simulate space-like conditions, predicting equipment behavior in challenging environments. Our centers provide testing across different chamber sizes and temperatures to meet diverse space application needs.

Our vacuum chambers come equipped with various electrical feedthroughs, ensuring seamless connectivity for test specimens during testing. This not only guarantees correct functioning but also allows for meticulous monitoring of the test object's behavior.

Electromagnetic Compatibility (EMC) Tests

Explore EMC testing excellence at Beyond Gravity Environmental Testing Center. Our facility offers EMC testing in shielded chambers across multiple locations, showcasing a commitment to precision and reliability. Additionally, we possess the capability to conduct reverberation measurements, ensuring comprehensive testing solutions for a diverse range of applications.

Antenna Testing

Discover advanced antenna testing at our Environmental Simulation Test Center featuring a dedicated RF lab and a cutting-edge 6-meter antenna measurement range. Our facility specializes in near and far-field measurements spanning from 900 MHz up to 40 GHz. Equipped with the latest test equipment, our setup includes automatic roll tables for swift and precise measurements.

Space Mechanism Testing

Explore state-of-the-art mechanical movement monitoring and evaluation at Beyond Gravity Environmental Testing Center. Our facility offers advanced proprietary methodologies, ensuring precision and reliability in assessing mechanical movements.

Interferometric Measurements

Explore precise Interferometric Measurements for Pointing Performance Testing in Cryogenic Environments at Beyond Gravity. Our capabilities include:

- Full 6 degrees of freedom (6 DoF) displacement measurement

- Exceptional accuracy of 1 nm

- Unmatched resolution at 1 pm

- Operating down to 15 K

- Conducted inside a liquid helium cooled cryostat

- Operation under high vacuum conditions

Electrical Ground Support Equipment (EGSE) Application

Explore the advanced capabilities of Electrical Ground Support Equipment (EGSE) Applications with Beyond Gravity. Our expertise includes:

- Function & performance testing

- High-level test automation

- TV test control

- Calibrated data acquisition

Highspeed Imaging and Motion Tracking (Photogrammetry)

Explore environmental simulation test center´s cutting-edge capabilities in High-Speed Imaging and Motion Tracking (Photogrammetry). With recording speeds of up to 1,000 frames per second (extendable to 100,000 with reduced resolution), we excel in capturing high dynamic processes. Our features include:

- Utilization of the latest tracking software

- Up to 8 synchronized simultaneous recording cameras

- Tracking and measuring objects in 3 dimensions

Mono Camera System for precise measurement of rotation in mechanisms:

- Accuracy: 0.02°

- Resolution: 0.005°

Multi-Camera System for comprehensive Measurements of 6 Degrees of Freedom (6 DoF) mechanisms:

- Accuracy: 50m/0.02°

- Resolution: 10m/0.005°

Space Test Center in Zurich

Have you seen which environmental tests are offered by Beyond Gravity Space Test Center in Zurich?